Development

R&D

Since the establishment of our affiliated research institute in 2011, Youngsin Metal Industrial has designed and built a wide range of

cold forging molds and has also developed the unique fastening components for both automotive and construction industries.

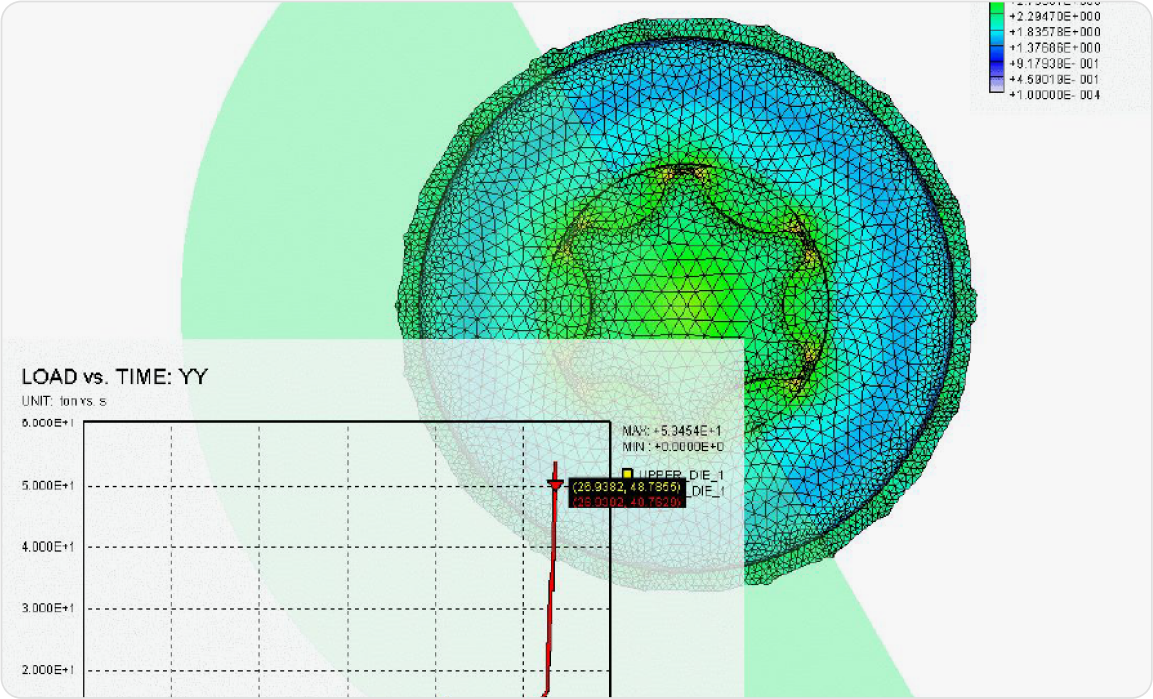

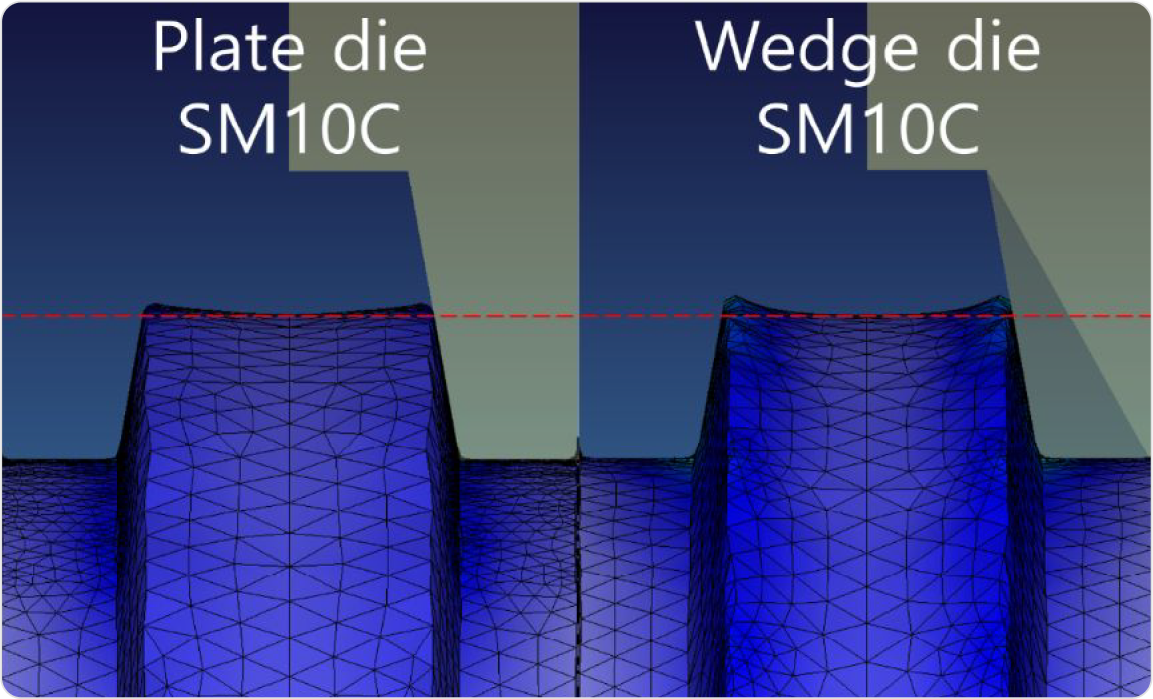

These components comply fully with our customer requirements because of our experience in fastener tool design aided by our

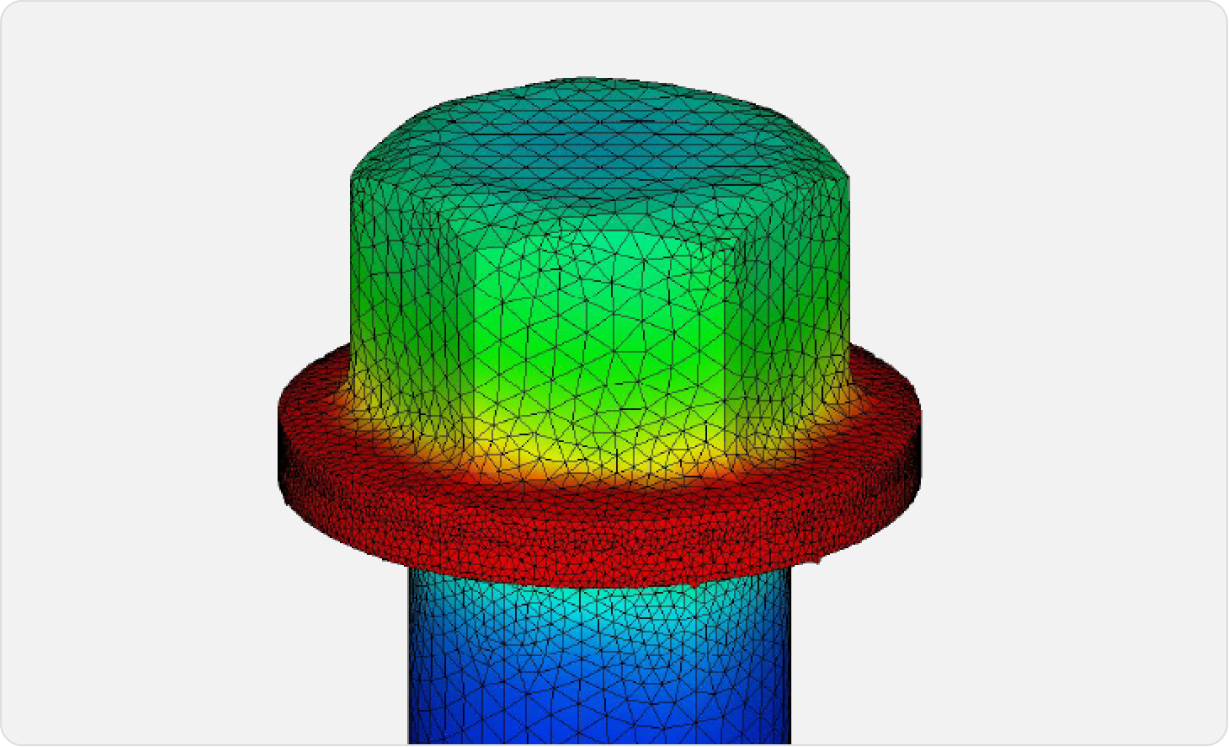

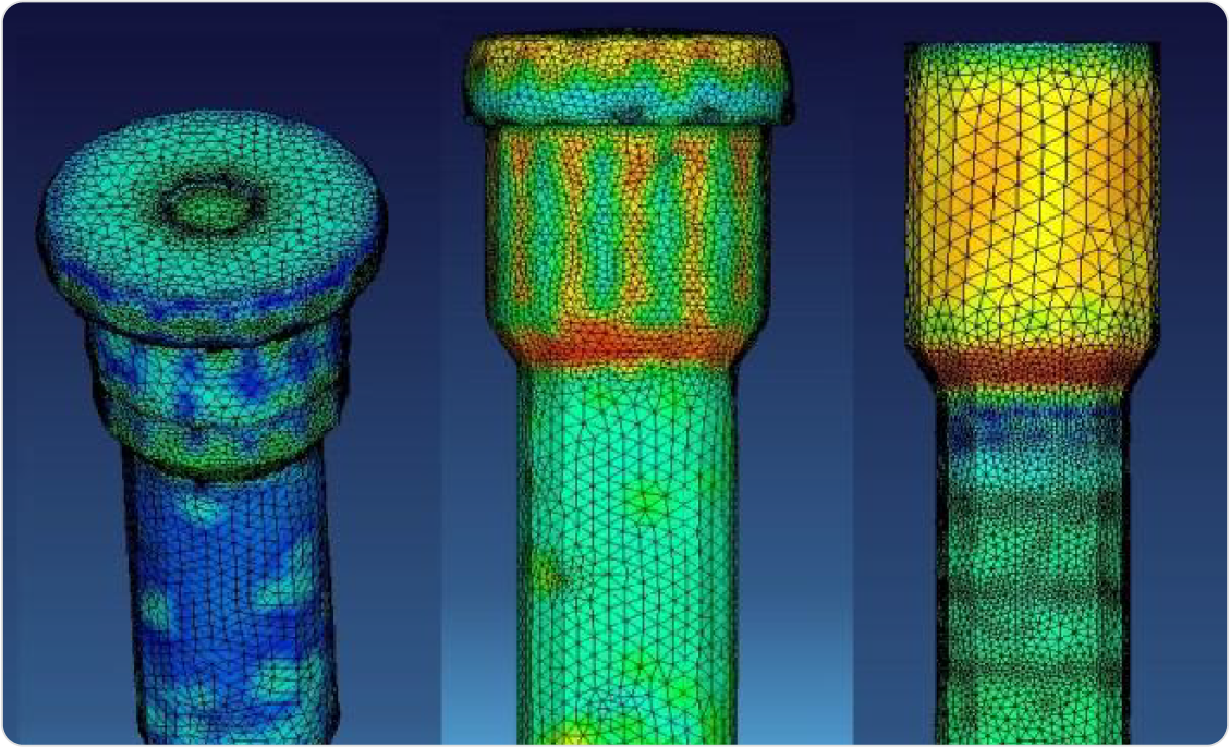

CAE finite element analysis of thousands of cold-forged products and preliminary verification of the simulation results.

-

Preliminary development

Preliminary development (pre-heat-treated steel,

high-strength lightweight aluminium bolts,

lead screws for automotive seats, rotor shafts for

power transmission in electric vehicles, etc.). -

Mold development

In-house mold design capabilities.

-

Product development

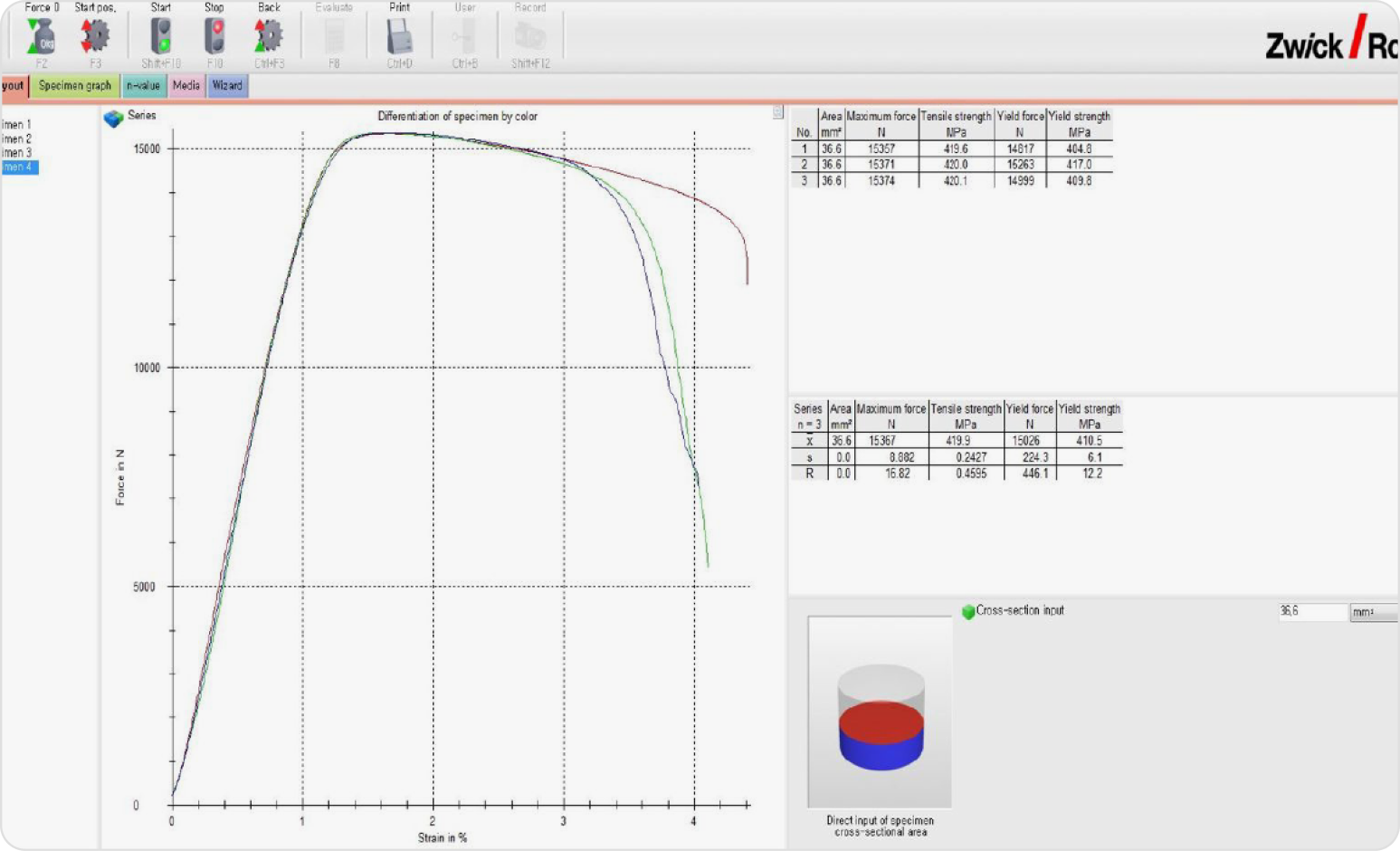

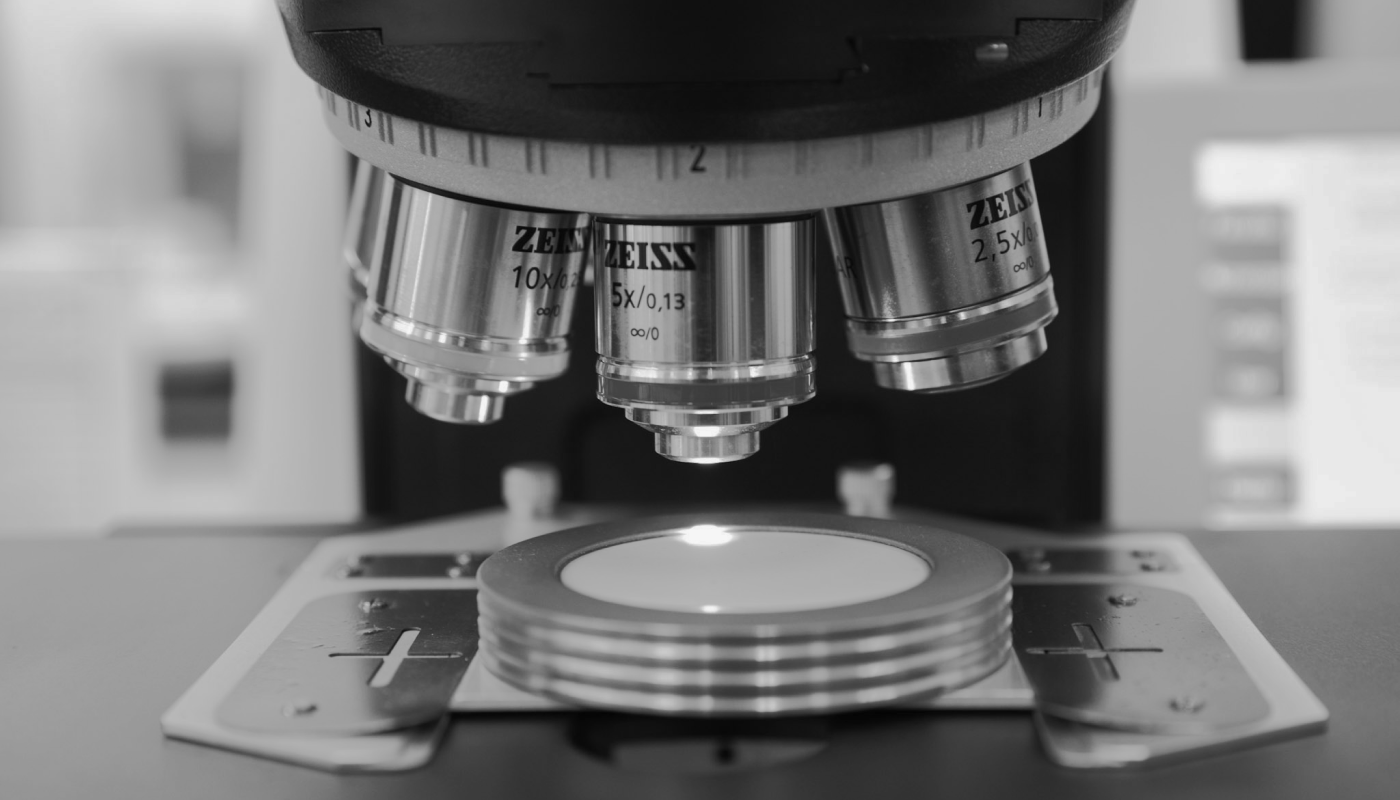

Material property and durability tests (tensile tests, axial

force tests (plastic region tightening conditions),

bolt fatigue tests, and salt spray tests (SST), etc.)

and cleanliness tests, also.

Virtuous-cycle

development system

-

Linear

Preliminary development

-

Mold

Mold development

-

Product

Product development

FEM simulation tool

-

AFDEX 2D/3D

Cold Forming Simulation -

-

Thread Rolling Analysis

by Stroke -

Finite element analysis using CAE

-

2D/3D Modeling

-

-

Development of

high-strength lightweight bolts -